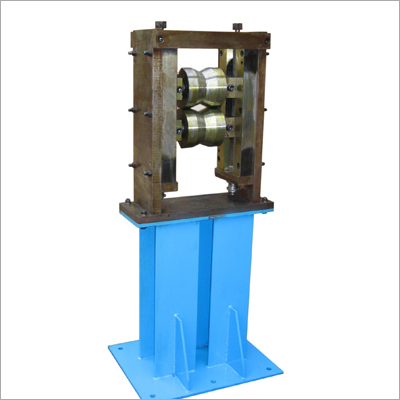

Idler Roller Assembly

Idler Roller Assembly Specification

- Thickness

- Roller shell thickness: 3 mm to 10 mm

- Surface Finish

- Galvanized/Powder Coated

- Belt Type

- Flat and Trough

- Power Source

- Manual/Mechanical

- Material

- Mild Steel, Rubber, Stainless Steel (depending on configuration)

- Type

- Idler Roller Assembly

- Structure

- Roller Frame with Cylindrical Rollers

- Belt Conveyor

- Compatible

- Roller Conveyor

- Compatible

- Vertical Conveyor

- No

- Pneumatic Conveyor

- No

- Resistant Feature

- Corrosion and wear resistant

- Load Capacity

- Up to 1000 kg

- Speed

- Dependent on belt system

- Usage & Applications

- Material handling, mining, cement, power plants, conveyor systems

About Idler Roller Assembly

Features:

-

Robust construction

-

Precise dimensions

-

Easy to install

-

Low inertia with high speed

Corrosion and Wear Resistance

Designed with high-grade materials and protective finishes, the Idler Roller Assembly excels in resisting corrosion and wear. This feature is essential for industries exposed to harsh conditions, minimizing maintenance needs and enhancing operational continuity. The option of galvanized or powder-coated surfaces provides an added layer of durability.

Versatile Compatibility and Structure

The assembly is adaptable to both belt and roller conveyor systems, with a roller frame supporting cylindrical rollers. Its compatibility with flat and trough belt types makes it suitable for a wide range of conveyor applications in material handling, cement, mining, and power facilities.

Built for Heavy-Duty Applications

With a load capacity of up to 1000 kg and roller shells ranging from 3 mm to 10 mm in thickness, this assembly is engineered for robust performance. It can withstand the rigorous demands found in exporting, manufacturing, and service sectors, offering reliable support for heavy and persistent use.

FAQs of Idler Roller Assembly:

Q: How does the Idler Roller Assembly enhance belt conveyor performance?

A: The assembly provides stable support and smooth movement for conveyor belts, ensuring even distribution of heavy loads (up to 1000 kg). Its precision-engineered rollers reduce friction, which extends the lifespan of both belts and the rollers themselves, improving overall system efficiency.Q: What materials are used in the construction of the Idler Roller Assembly?

A: Depending on configuration, the rollers and frame can be made from mild steel, rubber, or stainless steel. These materials are chosen based on the specific requirements for corrosion and wear resistance, as well as demanding industrial applications.Q: When should I consider replacing the Idler Roller Assembly?

A: Replacement is recommended if you notice excessive wear, noisy operation, frequent belt mistracking, or corrosion that affects structural integrity. Regular inspections in demanding environments like mining or cement plants help determine the optimal replacement interval.Q: Where can the Idler Roller Assembly be used effectively?

A: It is ideal for material handling systems in industries such as cement, mining, and power plants. It also serves exporters, manufacturers, service providers, suppliers, and traders, particularly those operating conveyor systems in India and similar environments.Q: What process is involved in installing the Idler Roller Assembly?

A: Installation typically includes securing the roller frame onto the conveyor structure, aligning the cylindrical rollers with the belt path, and ensuring the proper tension. Mechanical or manual processes may be used, with attention given to compatibility with flat or trough belt systems.Q: How does the corrosion-resistant feature benefit operations?

A: Corrosion and wear resistance lower lifecycle maintenance costs and minimize downtime by enabling long-term performance, even in harsh or outdoor settings. This safeguards productivity, particularly in sectors prone to abrasive or corrosive materials.Q: What advantages does the customizable roller shell thickness offer?

A: Variable roller shell thicknesses, from 3 mm to 10 mm, allow customization based on load, belt speed, and application requirements. Thicker rollers provide improved durability for heavy-duty operations, while lighter options are suited for less demanding uses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Roller Assembly Category

Plate Centering Roller Assembly

Belt Conveyor : Other, Compatible with standard belt conveyors

Surface Finish : Powder Coated / Galvanized

Type : Other, Plate Centering Roller Assembly

Material : Mild Steel with Zinc Plating

Roller Conveyor : Other, Included

Usage & Applications : Industrial material handling, steel plate alignment

Roll Invert Assembly

Belt Conveyor : Other, Not Included

Surface Finish : Powder Coated / Painted

Type : Other, Roll Invert Assembly

Material : Mild Steel with Powder Coating

Roller Conveyor : Other, Yes, Heavy Duty Rollers

Usage & Applications : Roll turning, positioning, and transferring in material handling and packaging industries

Drive Roller Assembly

Belt Conveyor : Other, Suitable for belt conveyor integration

Surface Finish : Powder coated or galvanized

Type : Other, Drive Roller Assembly

Material : Mild steel or stainless steel as per requirement

Roller Conveyor : Other, Designed for powered roller conveyor systems

Usage & Applications : Material handling, packaging, assembly lines, logistics

Vertical Guide Roller Assembly

Belt Conveyor : Other, Compatible with side belt guidance

Surface Finish : Zinc plated, Powder coated

Type : Other, Vertical Guide Roller Assembly

Material : High grade Mild Steel (MS), Zinc plated and/or powder coated

Roller Conveyor : Other, Compatible

Usage & Applications : Side guide for vertical conveyors, Material handling systems, Elevators, Lifts

Send Inquiry

Send Inquiry