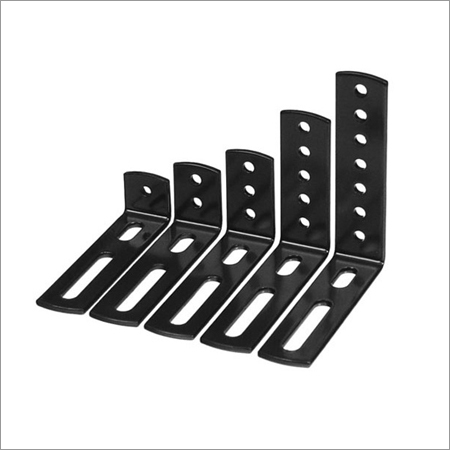

Guide Bracket Mounting

Price 200 INR/ Pair

MOQ : 100 Strands

Guide Bracket Mounting Specification

- Surface Finish

- Galvanized/Polished

- Usage & Applications

- Industrial Machinery, Conveyor Systems, Structural Support

- Protection Level

- Corrosion Resistant

- Coating Material

- Powder Coated/Galvanized

- Material

- Mild Steel/Steel/Stainless Steel

- Size

- Standard & Custom Sizes Available

- Fabrication Service Type

- Custom Metal Fabrication

- Fabrication Product

- Guide Bracket Mounting

- Fabrication Process

- CNC Bending, Welding, Cutting

About Guide Bracket Mounting

By following set industry standards, we are engaged in offering premium quality Guide Bracket Mounting. Cherished among our patrons for its compact size and high strength, the provided product is specially designed for mounting purposes. Further, the offered bracket is manufactured under the guidance of diligent professionals by utilizing high grade raw materials with the aid of contemporary techniques. Available in various dimensions and sizes, this Guide Bracket Mounting is offered at most reasonable rates to our clients.

Features:

-

Rugged design

-

Durability

-

Rust proof

-

Fine finish

Precision Fabrication for Reliable Support

We utilize advanced CNC bending, welding, and cutting processes to manufacture guide bracket mountings tailored for structural support. Designed for use in industrial machinery and conveyor systems, our brackets guarantee stability and durability in demanding environments.

Flexible Finishes and Materials for Every Application

Choose from galvanized or polished surface finishes, as well as powder-coated or galvanized coatings, to suit your specific protection and appearance needs. Fabricated from premium mild steel, steel, or stainless steel, our products provide exceptional rust resistance and long-term reliability.

Comprehensive Service from Concept to Delivery

As a leading exporter, manufacturer, supplier, and service provider in India, we offer end-to-end custom metal fabrication services. From standard offerings to fully customized solutions, our team ensures each guide bracket mounting meets rigorous industry standards.

FAQs of Guide Bracket Mounting:

Q: How does the guide bracket mounting fabrication process work?

A: The fabrication process involves precise CNC bending, welding, and cutting of mild steel, steel, or stainless steel to achieve the desired bracket shape and strength. Surface finishes like galvanization or polishing, as well as coatings such as powder coating, are applied at the final stages for protection and aesthetic improvement.Q: What are the applications of guide bracket mounting products?

A: Guide bracket mountings are commonly used in industrial machinery, conveyor systems, and various structural support scenarios. Their strength and corrosion resistance make them suitable for demanding environments where stability is crucial.Q: When should I opt for custom over standard sizes?

A: Custom sizes are ideal when your equipment or installation requires specific dimensions or unique load-bearing features not available in standard products. Our team can fabricate guide brackets to meet your projects exact requirements.Q: Where do you supply and export these guide bracket mounting products?

A: We supply and export guide bracket mounting solutions across India and internationally, serving clients in various industrial sectors as a reputable exporter, manufacturer, and supplier.Q: What surface finishes and coatings are available?

A: You can choose between galvanized or polished finishes for enhanced appearance and corrosion resistance. Additionally, powder-coated and galvanized coatings are offered to ensure long-lasting protection in harsh environments.Q: How does your fabrication service add value to customers?

A: Our custom metal fabrication service provides end-to-end support, from material selection and design to manufacturing and finishing. This approach guarantees the product meets precise specifications and delivers optimal performance and longevity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hardware Brackets Category

Fabricated Bracket

Fabrication Product : Fabricated Bracket

Fabrication Process : CNC Cutting, Welding, Bending, Punching

Fabrication Service Type : Customized Product Fabrication

Coating Material : Zinc / Epoxy / Polyester

Guide Bracket Short

Price 150000 INR / Pair

Minimum Order Quantity : 10 Pairs

Fabrication Product : Roller

Fabrication Process : Machining Welding

Fabrication Service Type : At our works

Send Inquiry

Send Inquiry