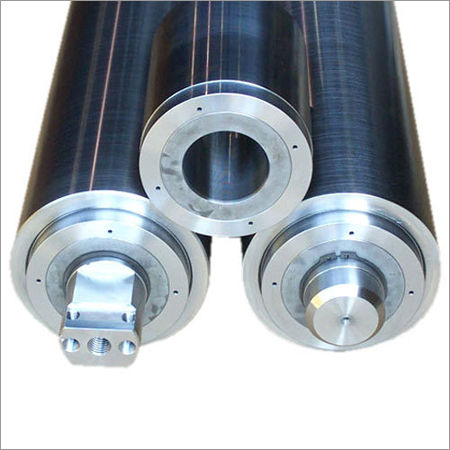

Diabolic Conveyor Roller

Diabolic Conveyor Roller Specification

- Thickness

- 2.2 mm to 3 mm (Tube Thickness)

- Surface Finish

- Smooth Zinc Plated or Powder Coated

- Belt Type

- Not Included

- Power Source

- Manual/Gravity

- Material

- Mild Steel/Steel with zinc or powder coated finish

- Type

- Diabolic Conveyor Roller

- Structure

- Tube with two conical ends on both sides

- Belt Conveyor

- Compatible (when used as roller sets)

- Roller Conveyor

- Yes, designed for roller conveyor systems

- Pneumatic Conveyor

- Not Supported

- Resistant Feature

- Corrosion and Abrasion Resistant

- Load Capacity

- Up to 200 kg per roller

- Voltage

- Not Required (Manual Operation)

- Speed

- Manual, depends on conveyor system

- Usage & Applications

- Material Handling, Warehousing, Packaging, and Automation

About Diabolic Conveyor Roller

Enriched with the year of industry experience, we are offering a wide assortment of Diabolic Conveyor Roller. Our provided roller is used for production line in factories and other construction sites. The offered conveyor roller is manufactured with the help of cutting-edge technology by making use of fine quality components under the stern guidance of our professionals at our well-equipped production unit. Moreover, this Diabolic Conveyor Roller is available in different sizes and other specifications to meet the specific requirements of clients.

Features:

-

Sturdy construction

-

Easy to operate

-

Noise free working

-

Longer service life

Reliable Performance in Material Handling

Diabolic Conveyor Rollers deliver dependable operation for manual or gravity-driven systems, supporting up to 200 kg per roller. The tubular structure with conical ends ensures smooth transfer and alignment on conveyor setups, ideal for warehouses, packaging lines, and automation facilities seeking efficient material flow without the need for external power.

Engineered for Longevity and Efficiency

Constructed from high-quality mild steel or steel, and finished with zinc plating or powder coating, these rollers provide exceptional corrosion and abrasion resistance. Their robust design extends service life and reduces maintenance, making them a preferred choice for high-throughput environments and industrial exporters.

Versatile Integration for Diverse Applications

These rollers are compatible with both roller and belt conveyors (when used as sets), offering flexibility across various material handling and automation processes. Their manual operation eliminates the need for electrical components, streamlining setup and reducing operational costs in any facility.

FAQs of Diabolic Conveyor Roller:

Q: How is the Diabolic Conveyor Roller installed in conveyor systems?

A: The Diabolic Conveyor Roller is easily integrated into both roller and compatible belt conveyor systems by placing it within the conveyor frame, ensuring that the conical ends fit securely and allow for smooth material movement. No electrical connections are needed due to its manual operation.Q: What are the main benefits of choosing a corrosion and abrasion resistant conveyor roller?

A: Choosing a corrosion and abrasion resistant roller, such as this model with zinc or powder coated finishes, ensures long-lasting performance even in demanding environments. It minimizes wear, reduces replacement costs, and maintains efficiency in material handling operations.Q: When should I consider using a Diabolic Conveyor Roller in my facility?

A: You should consider using these rollers when handling heavier loads (up to 200 kg per roller), especially in environments requiring durability and manual operationsuch as warehouses, packaging, or automation lineswithout reliance on electrical power.Q: Where can Diabolic Conveyor Rollers be commonly utilized?

A: These rollers are widely used in material handling, warehousing, packaging, and automation sectors, particularly in facilities that operate roller or compatible belt conveyor systems. They are supplied by Indian exporters, manufacturers, and service providers.Q: What is the process for maintaining these conveyor rollers?

A: Regularly check for debris or buildup on the roller surface, and ensure that the rollers spin freely. The corrosion and abrasion resistant coating simplifies maintenance, often requiring just occasional cleaning and inspection for optimal performance.Q: How do I benefit from using a manual, voltage-free conveyor roller system?

A: Manual operation eliminates the need for electrical infrastructure, resulting in lower operational costs and easier installation. It also enhances safety and reliability, making these rollers suitable for environments where power sources are limited or where simplicity is preferred.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Roller And Conveyor Category

Roller Guide For Pelletizer

Price Range 500.00 - 5000.00 INR / Pair

Minimum Order Quantity : 10 Pairs

Belt Conveyor : Other, No

Usage & Applications : Used in pelletizer machines for guiding and supporting pellet movement

Roller Conveyor : Other, Yes

Structure : Other, Compact and Rigid

Send Inquiry

Send Inquiry