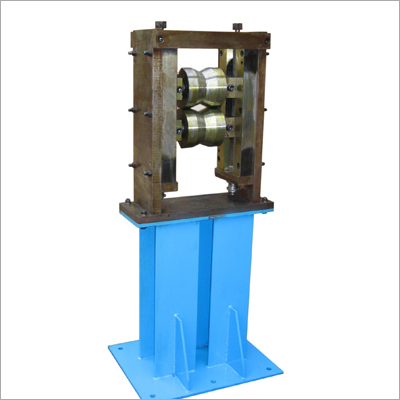

Vertical Guide Roller Assembly

Vertical Guide Roller Assembly Specification

- Power Source

- Mechanical

- Surface Finish

- Zinc plated, Powder coated

- Material

- High grade Mild Steel (MS), Zinc plated and/or powder coated

- Type

- Vertical Guide Roller Assembly

- Structure

- Heavy duty base plate with vertically aligned rollers

- Belt Conveyor

- Compatible with side belt guidance

- Roller Conveyor

- Compatible

- Vertical Conveyor

- Compatible

- Load Capacity

- Up to 500 kg per roller (customizable)

- Voltage

- Not required (manual/mechanical type)

- Power

- Not required (manual/mechanical type)

- Speed

- Variable, depends on system

- Usage & Applications

- Side guide for vertical conveyors, Material handling systems, Elevators, Lifts

About Vertical Guide Roller Assembly

Designed with precision and accuracy, this Vertical Guide Roller Assembly is manufactured in complete compliance with defined industry standards. Highly appreciated for its compact design and robust construction, this roller assembly is widely used in packaging, food processing, automobile and other industry. The offered system is engineered by utilizing quality approved metal alloys and other components. Our offered Vertical Guide Roller Assembly is available in numerous specifications as per the specific needs of the clients.

Features:

-

Less maintenance

-

Robust construction

-

Less power consumption

-

Impeccable performance

Reliable Performance and Customizable Load Capacity

Each roller in the assembly can support up to 500 kg, catering to various industrial material handling needs. Load capacity customization allows seamless adaptation to specific requirements, making these rollers ideal for elevators, lifts, and vertical conveyors in heavy-duty environments.

Durable Design with Advanced Surface Protection

Fabricated from premium Mild Steel and treated with zinc plating or powder coating, these rollers resist corrosion and extend lifespan. The heavy-duty base plate provides structural integrity. The visually appealing finish ensures low maintenance and lasting service even in demanding applications.

Manual Operation for Flexible Integration

Designed as a mechanical/manual system, the Vertical Guide Roller Assembly does not require voltage or external power, simplifying installation and integration. Variable speed operation depends on the conveyor system, making the assembly compatible with both side-belt and roller guided conveyors.

FAQs of Vertical Guide Roller Assembly:

Q: How do I install the Vertical Guide Roller Assembly in my conveyor system?

A: Installation involves mounting the heavy-duty base plate and aligning the rollers vertically along the conveyors side guide track. No electrical connections are needed, as the assembly functions mechanically.Q: What materials are used in the construction of the rollers and base plate?

A: The assembly is built using high grade Mild Steel (MS), which is zinc plated and/or powder coated to deliver superior strength, corrosion resistance, and longevity in industrial environments.Q: When should I choose a Vertical Guide Roller Assembly over other side guides?

A: Select this assembly when dealing with vertical conveyor or elevator systems requiring reliable mechanical guidance, heavy load capacity, and compatibility with both belt and roller conveyors.Q: Where can this assembly be used beyond conveyors?

A: Besides conveyors, the assembly is ideal for material handling systems, lifts, vertical elevators, goods hoists, and various industrial automation setups requiring controlled movement and support.Q: What is the process of customizing the load capacity per roller?

A: Customization involves consulting the supplier or manufacturer with your distinct load requirements. The assembly can be tailored by selecting appropriate roller specifications and base plate designs.Q: Is any electrical power required to operate this roller assembly?

A: No electrical power or voltage is needed. The Vertical Guide Roller Assembly operates through manual or mechanical means, which eliminates dependency on an external power source.Q: What benefits does the powder-coated or zinc-plated surface offer?

A: Powder-coating and zinc plating enhance durability by providing corrosion protection, better wear resistance, and a clean finish, resulting in reduced maintenance and extended operational lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Roller Assembly Category

Idler Roller Assembly

Belt Conveyor : Other, Compatible

Roller Conveyor : Other, Compatible

Surface Finish : Galvanized/Powder Coated

Resistant Feature : Other, Corrosion and wear resistant

Material : Mild Steel, Rubber, Stainless Steel (depending on configuration)

Usage & Applications : Material handling, mining, cement, power plants, conveyor systems

Drive Roller Assembly

Belt Conveyor : Other, Suitable for belt conveyor integration

Roller Conveyor : Other, Designed for powered roller conveyor systems

Surface Finish : Powder coated or galvanized

Resistant Feature : Other, Corrosion and wear resistant surface treatment

Material : Mild steel or stainless steel as per requirement

Usage & Applications : Material handling, packaging, assembly lines, logistics

Plate Centering Roller Assembly

Belt Conveyor : Other, Compatible with standard belt conveyors

Roller Conveyor : Other, Included

Surface Finish : Powder Coated / Galvanized

Resistant Feature : Other, Corrosion and Abrasion Resistant

Material : Mild Steel with Zinc Plating

Usage & Applications : Industrial material handling, steel plate alignment

Roll Invert Assembly

Belt Conveyor : Other, Not Included

Roller Conveyor : Other, Yes, Heavy Duty Rollers

Surface Finish : Powder Coated / Painted

Resistant Feature : Other, Corrosion Resistant

Material : Mild Steel with Powder Coating

Usage & Applications : Roll turning, positioning, and transferring in material handling and packaging industries

Send Inquiry

Send Inquiry