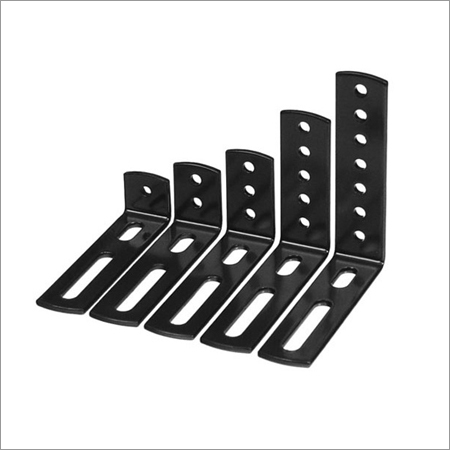

Fabricated Bracket

Fabricated Bracket Specification

- Surface Finish

- Powder Coated / Painted / Galvanized

- Size

- As per requirement / Customizable

- Protection Level

- Corrosion Resistant

- Coating Material

- Zinc / Epoxy / Polyester

- Usage & Applications

- Support for Panels, Beams, Construction, Machinery, Mounting Systems

- Material

- Mild Steel / Stainless Steel / Aluminum

- Fabrication Service Type

- Customized Product Fabrication

- Fabrication Product

- Fabricated Bracket

- Fabrication Process

- CNC Cutting, Welding, Bending, Punching

About Fabricated Bracket

The provided Fabricated Bracket is widely used in automotive industry for assembling the automotive parts. By making use of supreme quality raw materials and pioneering technology, the entire range of bracket is manufactured at our advanced production unit under the supervision of our adept professionals. Apart from this, the offered Fabricated Bracket can avail from us in various sizes and dimensions at affordable prices.

Features:

-

Precisely engineered

-

Strong construction

-

Compact size

-

Easy to install

Superior Fabrication Precision

Every fabricated bracket is produced using advanced CNC cutting and precise welding processes that guarantee accuracy and structural integrity. Our team expertly handles bending and punching according to client specifications, ensuring optimal fit and functionality for your unique project requirements.

Custom Finishes and Maximum Protection

Choose from powder coated, painted, or galvanized finishes to achieve both aesthetic appeal and enhanced protection. Our zinc, epoxy, and polyester coatings are carefully selected to boost corrosion resistance, making these brackets suitable for demanding environments and prolonged operational life.

Versatile Applications in Construction and Industry

Designed for adaptability, our brackets provide reliable support for panels, beams, mounting systems, and heavy machinery. They are widely used in construction, industrial assembly, and specialized mounting applications, offering both strength and customization tailored to diverse usage needs.

FAQs of Fabricated Bracket:

Q: How is the fabricated bracket customized for different applications?

A: The bracket is tailored to your required size and specifications through processes like CNC cutting, welding, and bending. You can select the material, finish, and coating for the desired level of strength and corrosion resistance, ensuring suitability for your unique application.Q: What materials are available for manufacturing the fabricated brackets?

A: We offer brackets manufactured from mild steel, stainless steel, or aluminum. Each material is chosen based on factors like required load capacity, environmental conditions, and application specifics to guarantee optimal performance.Q: When should a powder-coated, painted, or galvanized finish be selected?

A: Select the coating based on your environment and intended use. Powder-coated and painted finishes are ideal for indoor and decorative applications, while galvanized finishes with zinc or epoxy coatings are best for outdoor or corrosive settings. Our experts can recommend the best option for your needs.Q: Where can fabricated brackets be used?

A: These brackets are commonly utilized in construction, supporting panels and beams, as well as in machinery and mounting systems. Their robust design and customizable nature make them suitable for versatile installation locations, including factories, commercial buildings, and infrastructure projects.Q: What is the typical fabrication process for these brackets?

A: The process involves CNC cutting the raw material to your specifications, followed by welding, bending, and punching. The bracket is then finished with a surface treatment of your choice, such as powder coating, painting, or galvanizing, to enhance durability and corrosion resistance.Q: How does corrosion resistance benefit the longevity of the bracket?

A: Corrosion-resistant finishes, including zinc, epoxy, or polyester coatings, provide a protective barrier against moisture, chemicals, and environmental exposure. This ensures the bracket remains structurally sound and maintains its appearance over time, minimizing maintenance and replacement costs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hardware Brackets Category

Guide Bracket Mounting

Price 200 INR / Pair

Minimum Order Quantity : 100 Strands

Fabrication Process : CNC Bending, Welding, Cutting

Fabrication Service Type : Custom Metal Fabrication

Fabrication Product : Guide Bracket Mounting

Material : Mild Steel/Steel/Stainless Steel

Guide Bracket Short

Price 150000 INR / Pair

Minimum Order Quantity : 10 Pairs

Fabrication Process : Machining Welding

Fabrication Service Type : At our works

Fabrication Product : Roller

Send Inquiry

Send Inquiry